Junior Year

RedZone Robotics Co-op

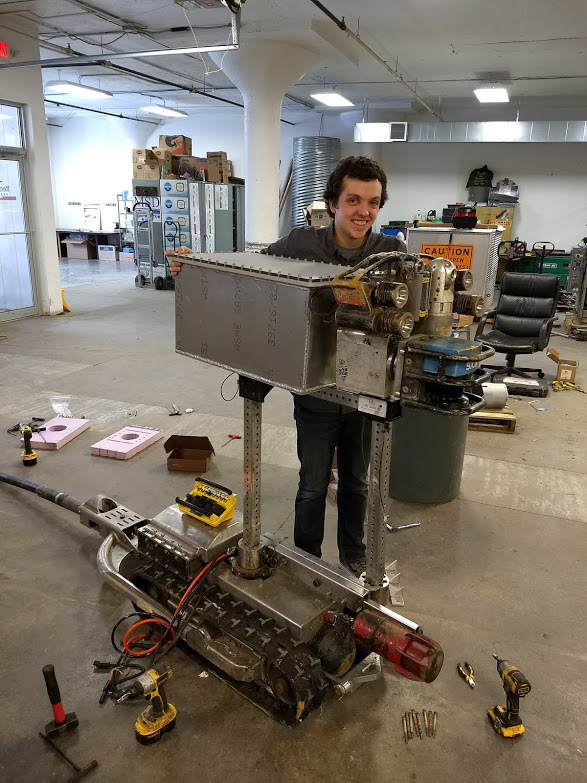

I participated in the engineering co-op program at Pitt. A co-op is where you alternate between work and school every semester. The company I completed three rotations with was RedZone Robotics. The co-op program gave me a total of one year of working experience. Two weeks into my first rotation, the person who hired me and the only mechanical engineer at the Pittsburgh location left the company. Right after he left, me and the other mechanical engineering co-op were tasked with modifying an existing camera to be used for over 100 different inspections. We had to essentially rebuild it from the ground up manufacturing all the parts ourselves on the mill and lathe. While the device was slow and bulky to use, we got it functional and it did its job.

Another one of my tasks at RedZone was cleaning, repairing, troubleshooting, and rebuilding LIDAR assemblies that returned from the field. I ended up developing an inventory sheet for the repair room to have a better idea of what was in stock and when part needed to be ordered.

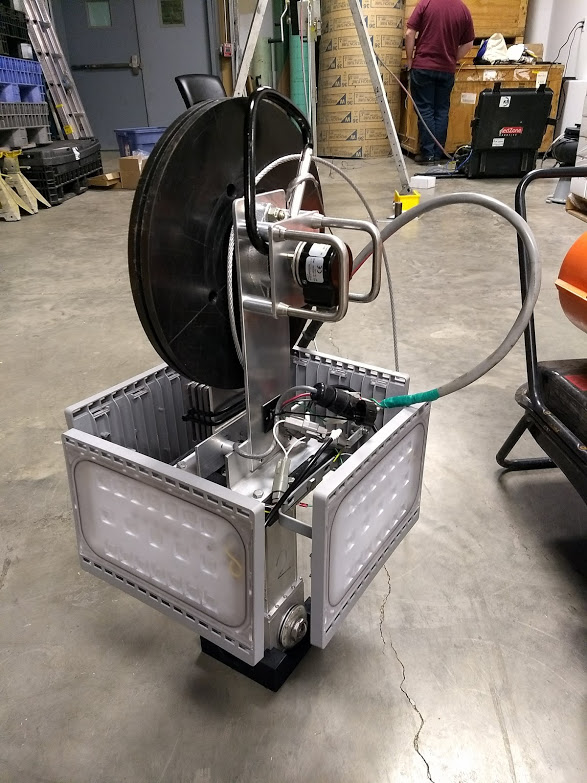

For my final project at RedZone, I and my two fellow co-ops were tasked with developing a new autonomous manhole inspection platform from the ground up. We talked to the sales team, the reporting team, the field crew, the engineering team, and an industrial designer to compile a list of requirements. We then designed, developed, manufactured, and tested and initial prototype of our design. The head of the field crew said it was one of the best pieces of equipment he had seen come from the company in years.